Construction and Concrete Silicone Sealant

Neutral Silicone Sealant

Features

- Good unprimed adhesion to a variety of substrates.

- Neutral cure

- Low odor

- Conforms to ISO 11600-F-25LM

- Resistant to ozone, ultra-violet radiation and extreme temperatures

- Joint movement capability ±50%

- Excellent weatherability –virtually unaffected by sunlight, rain,snow, ozone and extreme temperatures of -40°C to 149°C

Applications

- Dowsil 813C Construction and Concrete Silicone Sealant is a one- part, neutral curing, low modulus silicone sealant particularly suitable for interior and exterior applications, such as external weather seals, expansion joints and perimetral joints in buildings and other types of construction.

- Dowsil 813C Silicone Sealant offers durable adhesion to a range of porous and non-porous surfaces including concrete, masonry, brick, PVC-U, wood and some metals used in construction without danger of corrosion from the sealant.

Typical Properties

How to Use

Surface preparation

Ensure that surfaces to be sealed are clean, dry, sound and grease-free. Clean non-porous surfaced with

Dow Corning® R40 Universal Cleaner, and dry thoroughly with a clean, lint-free cloth before application of sealant. Porous substrates such as concrete, brickwork, mortar, etc. must be mechanically cleaned of loose particles using a steel brush, sanding disc or any similar means.

Note: When using any solvent, always provide adequate ventilation. Avoid heat, sparks and open flames. Use solvent resistant gloves. Observe and follow all precautions listed on solvent container label.

Masking

Areas adjacent to the joints should be masked with tape to prevent contamination of the substrates and to ensure a neat sealant line. Masking tape should be removed immediately after tooling.

Priming

Primers are not usually required but might be needed for some specific substrates for maximum adherence. For specific advice, please contact your local Technical Services.

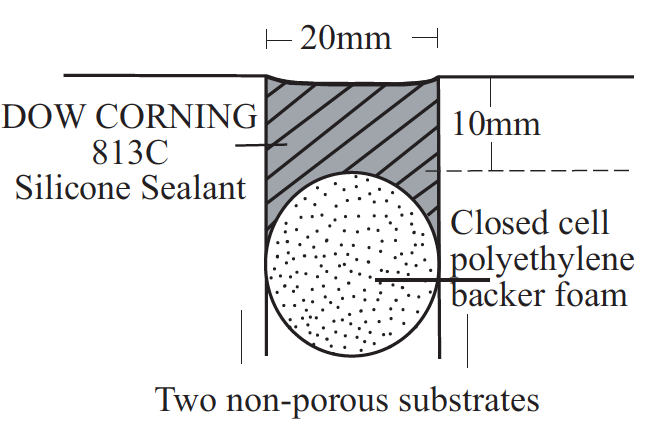

Back-up materials

Where back-up material is required, closed cell polyethylene backer rod is recommended. Back-up materials provide back pressure and avoid three sided adhesion that limits sealant movement capability.

Finishing

The joint should be tooled within 5 minutes of application to ensure good contact between the sealant and the substrate. Tooling of the sealant also gives a smooth, professional finish.

Clean-Up

Excess sealant may be cleaned off tools and non-porous surfaces whilst in an uncured state using Dow Corning® R40 Universal Cleaner. If sealant is misapplied to porous substrates, it should be left until it is just cured and then removed by peeling, cutting or other mechanical means. Care should be taken not to damage plastic or coated surfaces.

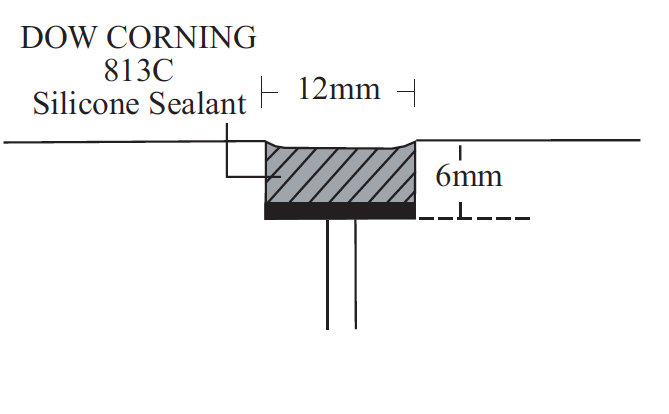

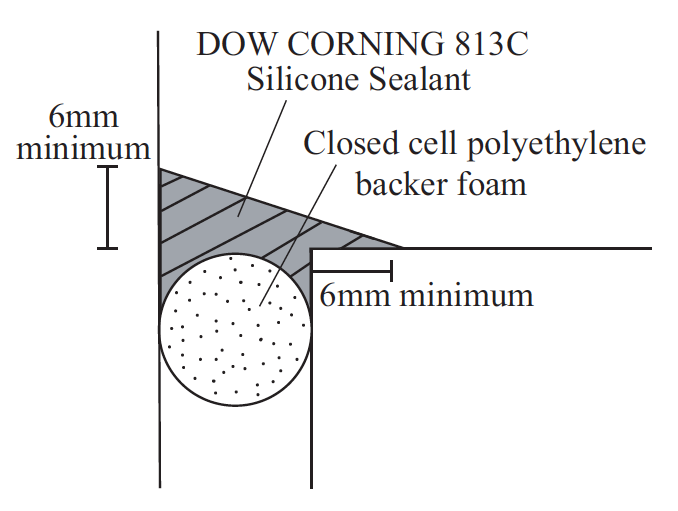

Joint Design

The sealant joint width should be designed to accommodate the movement capability of the sealant. When designing joints using Dowsil 813C Silicone Sealant, the minimum width should be 6mm.

For joints between 6-12mm wide, a seal depth of 6mm is required.

For joints above 12mm wide, a width to depth ratio of 2:1 should be used.

In situations where fillet joints are needed, a minimum of 6mm sealant bite to each substrate is recommended. For joint dimensions with a width greater than 25mm or a depth greater than 15mm, please contact your local Technical Services.

Figure 1: Deep Joint

Figure 2: Shallow Joint

Figure 3: Fillet Joint

Technical Services

Your Dow Corning contact details (e-mails):

Technical inquiries:

Marketing:

Quality Bond:

EHS inquiries:

Reach inquiries: [email protected]

Your Technical Service contact details (phone):

Toll Free Numbers:

From Belgium +0800 80 522

From France +0805 54 04 39

From Germany +0800 52 50 258

From Italy +800 92 83 30

From Spain +900 813161

From United Kingdom

+0800 9172 071

All other countries:

For English +32 64 51 11 59

For French +32 64 51 11 59

For German +49 611 237503

For Italian +32 64 51 11 73

For Spanish +32 64 51 11 66

For Russian +7 495 725 43 19

Fax number from all countries: +32 64 88 86 86

Handling Precautions

Product safety information required for safe use is not included in this document. Before handling, read product and material safety data sheets and container labels for safe use, physical and health hazard information. The material safety data sheet is available on the dow corning website at dowcorning.com, or from your dow corning sales application engineer, or distributor, or by calling dow corning customer service.

Usable Life & Storage

Dowsil 813C Silicone Sealant should be stored in cool and dry conditions.

When stored at or below 30°C in the original unopened containers, Dowsil 813C Silicone Sealant has a usable life of 12 months from the date of production.

Packaging Information

Dowsil 813C Silicone Sealant is supplied in 310ml cartridges packed in boxes of 12 and 600ml sausages packed in boxes of 20.

Colors

Dowsil 813C Silicone Sealant is available in the following colours:

White, stone, sand, desert rose, grey, red beige, pink coral, anthracite, brown, bronze, dark brown, custom color.

Limitations

Do not use Dowsil 813C Silicone Sealant on bituminous substrates, substrates based on natural rubber, choloroprene or EPDM or on building materials and flexible plastics which might bleed oils, plasticizers or solvents. Do not use Dowsil 813C Silicone Sealant in a totally confined space because the sealant requires atmospheric moisture to cure. Dowsil 813C Silicone Sealant is not recommended for use on submerged joints or in joints where physical abuse or abrasion is likely to occur. Bleeding can occur on porous substrates such as marble, granite or other natural stones. On sensitive substrates, specific testing should be carried out.

This product is not suitable for areas where food contact is likely.

Dowsil 813C Silicone Sealant is not recommended for structural glazing, insulated glazing or other glazing applications.

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

Health & Environmental Information

To support Customers in their product safety needs, Dow Corning has an extensive Product Stewardship organization and a team of Product Safety and Regulatory Compliance (PS&RC) specialists available in each area.

For further information, please see our website, dowcorning.com or consult your local Dow Corning representative.

Limited Warranty Information – Please Read Carefully

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.

Dow Corning’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted.

DOW CORNING SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DOW CORNING DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

We help you invent the future. ™

dowcorning.com