Highly elastic, durable, low maintenance liquid membrane for waterproofing

abeproof liquid membrane is a single pack, solvent borne, rubberised, liquid applied waterproofing membrane that is highly elastic and durable, requiring low maintenance.

Uses

abeproof liquid membrane can be used to waterproof most building substrates typically:

- Non-porous screeds, concrete, wood, polyurethane and bituminous surfaces

- For the refurbishment of existing, new and old bitumen membranes without the removal thereof

PRIME

COAT

COVER

Advantages

- Seamless, detail free singular membrane

- Superior water resistance, stands up to water ponding

- High elasticity and durable offering good tensile resistance

- Excellent thermal stability

- Excellent adhesion to most prepared substrates

- Fast curing, second coat applied after 4 hours and full cure in 24 hours

- Moisture insensitive, can be applied in cool, warm and humid conditions

- No fabric reinforcement required for standard applications

- UV stable, non-yellowing and standard reflective overcoating may be applied

- Quick turn-around time in simplicity of application makes it economical

- Contains a minimum of 10% recycled product

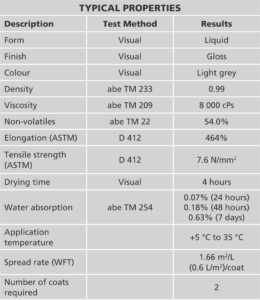

Typical Properties

Surface Preparation

All surfaces are to be clean, sound, free of all laitance, grease, all fungal growth and loose flaking particles. This could be achieved by wire brushing or suitable high pressure washing, finally rinsing with clean water.

New galvanised iron:

The surface has to be thoroughly cleaned using sugar soap or any other grease cutting detergent to remove oils followed by thorough rinsing or high pressure washing using clean water to reveal a clean, sound, water break free surface.

Old galvanised iron:

Remove all loose rust, dirt, salts of zinc corrosion and scale by means of wire brushing, sanding, chipping, or mechanical scouring — down to bright metal followed by thorough rinsing or high pressure washing using clean water to reveal a clean, sound, water break free surface.

Wood:

A solvent wipe using MEK or oil free acetone to remove any natural wood oil prior to application.

Mixing

Slow mixing or thorough stirring using a flat paddle just to re-homogenise the product before application.

Priming

Priming is a surface conditioner that offers optimum performance of the product.

• All surfaces are to be primed using one coat of abeproof liquid membrane primer prior to the application of the abeproof liquid membrane

• Some porous surfaces such as Asphalt, wood or bitumen deficient surfaces may require additional coats of the abeproof liquid membrane primer

• Galvanised and metal surfaces – prime with 4-metal primer

Application

When a primer is used allow the abeproof liquid membrane primer to dry for 45 minutes before applying the abeproof liquid membrane top coats.

The product may be applied by brush, short nap roller or airless spray equipment.

Two coats are required allowing 4 hours between coats, each coat is to be applied at a rate of 0.600ℓ/m2/coat WFT (1.66 m2/ℓ/coat) resulting in a minimum of 600 μm DFT (dry film thickness) for the full application.

(20ℓ will cover approximately 16 m2)

Top Coat

silvakote® eco or super laycryl® (emulsion based) are used to provide UV protection to exposed areas of abeproof LM liquid waterproofing membrane, applied in two coats, the first coat at 2.2 m2/ℓ and the second coat at 2.5 m2/ℓ.

Protection on Completion

All surfaces require suitable protection from dirt and contamination between coats and until the final coating has fully cured.

Coverage

Approximate coverage:

1ℓ will cover 1.66 m2/coat providing a WFT of 600 μm per coat, 2 coats are required.

(20ℓ will cover approximately 16 m2)

Model Specification

A highly elastic, durable, low maintenance liquid membrane for waterproofing.

The waterproofing will be abeproof liquid membrane, single pack, solvent borne, low VOC, liquid applied waterproofing membrane applied in two coats at a rate of 0.6 L/m2 per coat in accordance with the recommendations of a.b.e.®

Packaging

abeproof liquid membrane is supplied in:

5 litre (code: 95202005)

20 litre (code: 95202020)

Cleaning

Tools and mixing equipment should be cleaned immediately after use, and before the material has set with abe.®super brush cleaner, followed by washing with soap and water.

Handling & Storage

abeproof liquid membrane has a shelf life of 12 months if kept in a dry, cool store in the original, unopened packs. If stored at high temperatures and/or high humidity conditions, the shelf life may be reduced.

Health & Safety

Suitable protective clothing, gloves, eye protection and respiratory protective equipment should be worn.

Ensure adequate ventilation and do not smoke, use flame or naked lights during application. If material is splashed into the eye, wash with plenty of clean water and seek medical attention.

This data sheet is issued as a guide to the use of the product(s) concerned.

Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot – because a.b.e.® has no direct or continuous control over where and how a.b.e.®’s products are applied – accept any liability either directly or indirectly arising from the use of a.b.e.®’s products, whether or not in accordance with any advice, specification, recommendation or information given by the company.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction technology.

Conditions Of Warranty

The product (abeproof liquid membrane) must be applied as per the recommendations and specifications per the datasheet.

Conditions of the 10 year product warranty will be dependent upon the various methodologies employed.